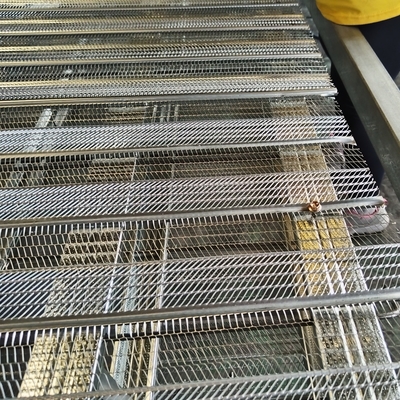

Construction Formwork Concrete Metal Mesh Galvanized Steel Rib Lath

Production description

Galvanized rib lath is is a re-enforcing mesh with rigid ribs running along the length of the sheet. It is used as a key for plaster and render applications although it differs from the normal mesh because of the ribs it can accommodate a deeper two coat render application. It can also be used for partition walls and ceilings. Can generally fixed through the rib with a nail or through the sheet with a staple or tying wire.

Rib lath is used in applications related to structural work, concreting, projecting insulation, or metal/wooden frame coating.

Rib lath ensures flatness, rigidity, good adhesion and is suitable for major construction work such as reinforcement , formwork for foundations , slabs , walls, seals and other uses.

Product specifications

| Name |

Galvanized Rib Lath Cement Pouring Formwork Structure |

| Material |

Galvanized steel |

| Size |

1.1m*3m or customized |

| Weight |

11kg/sqm |

| Rib lath |

0.4mm thickness |

| C-profiles |

0.6mm thickness |

| Connectors |

1.5mm thickness, 20*19mm |

| Rebar |

5mm diameter, 700N/mm² traction strength |

| Feature |

Long lasting, enhance strength, light weight, save time |

| MOQ |

1pcs |

Product advantage

1.Excellent Bond with Concrete

The mesh and rib structure allows concrete to pass through and interlock, resulting in strong mechanical bonding between the concrete and the lath.Reduces risk of surface delamination or poor adhesion.

2.Lightweight and Easy to Handle

Much lighter than traditional formwork panels like plywood or steel plates.Easier to cut, shape, and install, especially in complex or curved structures.

3.No Need for Formwork Removal

Acts as permanent formwork—it stays in place after the concrete sets.

Saves labor and time because there's no need for stripping or dismantling.

4.Cost-Efficient

Reduces the need for traditional formwork materials and labor.

Minimizes wastage and handling costs.

Product application

High and low-rise residential light compartments, firewalls;

Construct a partition, a compartment;

the floor of the building, the partition wall;

Permanent interior and exterior walls and walls of permanent buildings;

the basement moisture-proof duplex wall.

Work seams with structural combination;

Tunnels, sewers, and wall works;

cutting foundation, dock, retaining wall;

flat and arched floor;

Nuclear power plant, storage tank and other arc-shaped structures;

Special projects such as landscaping sculptures;

Slope protection, earth embankment and other projects.

About us

Founded in 2000, our workshop started as a 10-person team under the leadership of Mr. CUI (Our General Manager). By 2010, we expanded our workshops to 5000 sqm with complete departments including Production, Sales, After-sales, Technology, Research and Development, Procurement, and Design.

Today, Anping Velp Wire Mesh Products Co., Ltd has developed an enviable reputation for research, development, and as the premier option for expanded metal, perforated metal mesh, safety walkway grating, stainless steel 304/316 weave mesh, and building stucco mesh products in China.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!