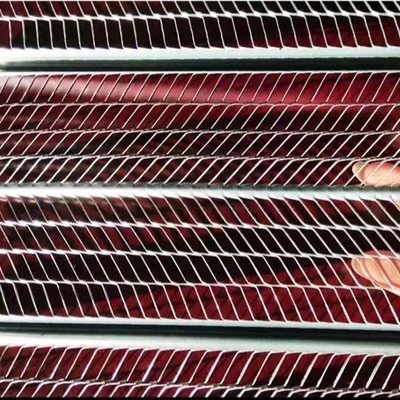

Galvanized Building Mesh Expanded Metal Rib Lath Panel

Production description

We manufacture which is a patented structural stay-in-place formwork system, used to build load-bearing walls. It consists of two filtering grids that are made of rib lath which are reinforced by vertical stiffeners and connected using rebar loops. It is quite easy to use as the workers just have to create a structure using and pour concrete into it. After some time, excess water is removed from concrete by gravity through grids. This prevents concrete aging, cracks, porosity, and bleeding in the structure.

Unlike traditional column and beam which takes 18 to 24 hours to install, our formwork only takes 3-4 hours. Due to this reason, it can reduce the construction time. In few days, workers whether they are qualified or not can be trained on the technology. Moreover, making strucutres from this formawork is less physically demanding than conventional ones. All of these things can help in dealing with the problem of labor shortage.build structures are strong enough to deal with the earthquake and other disasters because of rebar loops that are used to connect the grids. In comparison to bricks, it is not made of fire which is created by burning wood. That is why, indirectly, our product is environmental friendly.

Product specifications

| Name |

Galvanized Rib Lath Cement Pouring Formwork Structure |

| Material |

Galvanized steel |

| Size |

1.1m*3m or customized |

| Weight |

11kg/sqm |

| Rib lath |

0.4mm thickness |

| C-profiles |

0.6mm thickness |

| Connectors |

1.5mm thickness, 20*19mm |

| Rebar |

5mm diameter, 700N/mm² traction strength |

| Feature |

Long lasting, enhance strength, light weight, save time |

| MOQ |

1pcs |

Product advantage

Features raised ribs or stiffening channels for added strength and rigidity.

Helps distribute loads evenly, reducing cracking in plaster or stucco finishes.

Easy to handle and install but provides strong reinforcement for wall and ceiling systems.

Metal rib lath enhances fire-rated assemblies by providing a non-combustible backing.

Product application

1.Slabs and Beams (Ribbed or Waffle Slabs)

Used as soffit formwork (underside of slab).

Supports wet concrete while allowing good bonding and curing.

Eliminates need to strip the formwork afterward.

2.Retaining Walls and Shear Walls

Acts as a permanent form face.

Ideal where one-sided formwork is used (e.g. retaining walls against soil or rock).

Allows reinforcement to be placed easily and concrete to be poured directly.

3.Curved or Irregular Shaped Structures

Easily bent or cut to fit arches, domes, curved walls, or decorative concrete elements.

Great flexibility compared to rigid formwork systems.

4.Tunnel Linings and Underground Works

Used for formwork in tunnels, culverts, shafts, and other underground structures.

Enables quick installation and better handling in tight spaces.

About us

Founded in 2000, our workshop started as a 10-person team under the leadership of Mr. CUI (Our General Manager). By 2010, we expanded our workshops to 5000 sqm with complete departments including Production, Sales, After-sales, Technology, Research and Development, Procurement, and Design.

Today, Anping Velp Wire Mesh Products Co., Ltd has developed an enviable reputation for research, development, and as the premier option for expanded metal, perforated metal mesh, safety walkway grating, stainless steel 304/316 weave mesh, and building stucco mesh products in China.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!