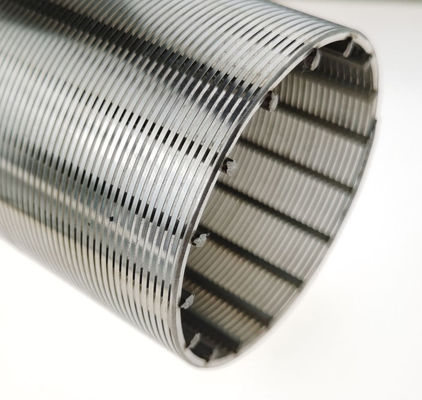

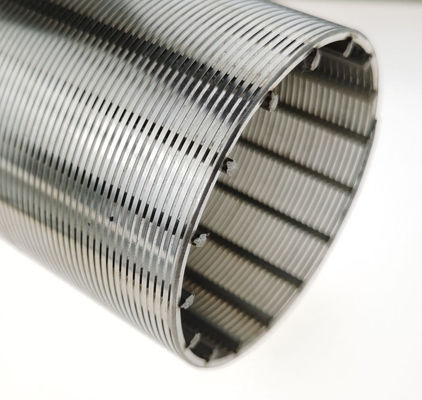

0.2 0.3 0.5 0.75mm slot 304SS wedge wire flat screen filter mesh for Static sieve screen

Product Description:

V wire water well screens, wire wrapped screens pipe, Johnson Screen, spiral screen tube, welded wedge wire screen, reversed slot screen, continuous slot pre-pack, water filter, screen cylinders, stainless steel slot tube, reverse rolled screen, strainer pipe, continous slot wire wrap well screens, pipe base well screen, ribbed-type wire wrapped screen, stainlss steel or low carbon galvanized or mild steel wire screen, wire wrapped liner, woven wedge wire screen, slot wire screen tube, conical well screen, Suction strainers, strainer screens, wide slit screens, well point screens, PPS screen, oil screen tube.

Wedge Wire screen cylinders can be designed with slot openings and wires running radially on the outside surface of the screen cylinder (above left) or they can be positioned axially on the inside of the cylinder (above right) Screen cylinders are manufactured in various diameters from 1/2" pipe size to 35" diameter.

Screen cylinders (above right) can be fabricated into larger diameters. Each intersection of wedge wire and support rod is welded for strength and durability. Various wedge wire and support rod combinations can be used to produce the bestscreen design. Rotary Screens typically use wedgewire for the screening media.

Specification:

| Item |

Size(mm) |

| Wedge wire |

0.5x1.5 0.75x1.5 1x2 1.5x2 2x3 2x4 3x5 |

| Support rod |

1.5x2.5 1.8x2.5 2x3 2x4 3x5 3x6 3x10 4x7 5x6 5x8 |

| Slot |

20 micron to 3000 micron,tolerance +-5 micron |

Wedge Wire Screen Diameter:

Screen diameters range from 0.750" to 38" and up in fabricated sections. Your specific tolerance and size requirements will be adhered to and will meet the required industry standards.

Wedge wire screen material: Stainless steel 304,316,316L etc.

Wedge wire screen mainly production process: wedge wire profiling and welding,cutting and other fitting welding,surface treatment,certification,package.

Wedge wire screen feature:

1. Smooth surface ,small slot sizes, accurate efficiency.

2. Stainless steel material corrosion, rust, chemical resistance, make wedge wire screen durable and long lifespan.

Wedge wire screen mainly used for liquid ,particles and powder filtering ,such as:Chemical industrial,pulp and paper industrial,mining industrial,brewing industrial,sewage instrument,oil and gas industrial etc .

Contact:

Please feel free to contact us if you have any questions, customized sheet.

MS.Lisa

tel 0086 183 3180 3300

email: sale1@velpwiremesh.com

The benefits of using wedge wire:

- Extended lifetime

- Slot during abrasive operation on the screen surface does not change

- Capability to withstand heavy loads

- High open area

- Less prone to clogging

- Perfectly smooth and flat surface

- High precision of execution Increased capacity and more precise separation

- Self-cleaning effect

- Low pressure loss

- Increased efficiency

- Permanence of exploited resources

- Lower capital cost and maintenance

Package:

1. Plywood case + safety belts + pvc films

2. carbon steel pallet + safety belts + pvc films

Transportation:

By air :2-3 days

By sea :35 days around

By express: 3-7 days

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!