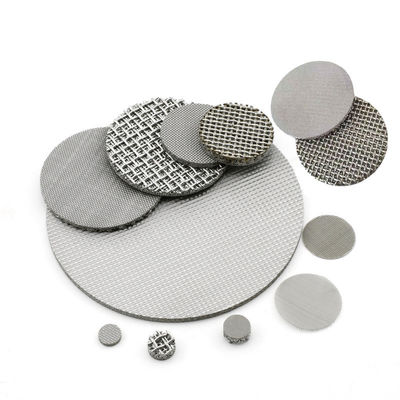

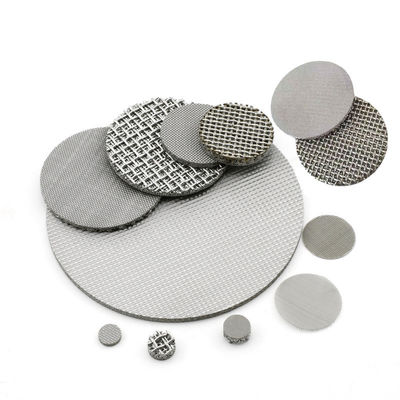

Multi-Layer High Filtration Sintered Mesh for Hydraulic Oil Filtration

Stainless steel sintered mesh is a versatile filtration and separation material created by bonding multiple layers of stainless steel woven wire mesh together through a sintering process. This involves applying heat and pressure in a controlled environment, causing the wires to fuse at their contact points, creating a strong and porous structure without the need for adhesives.

Structure and Manufacturing:

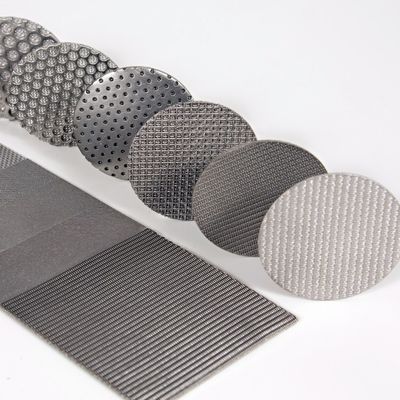

Typically made from multiple layers (often 2 to 5) of woven stainless steel wire mesh with varying weave patterns and wire diameters to achieve specific filtration properties.

The sintering process (diffusion bonding) creates a permanent bond at the wire intersections, enhancing the mesh's strength, rigidity, and dimensional stability.

Some designs incorporate a perforated metal layer for added support and robustness.

Common stainless steel grades used are 304, 316, and 316L due to their excellent corrosion and temperature resistance.

Applications:

Stainless steel sintered mesh is used across numerous industries for filtration, separation, diffusion, and fluidization, including:

Filtration:

Liquids: Polymers, chemicals, pharmaceuticals, food and beverage (water, milk, flour), hydraulic fluids, oil and gas, wastewater treatment.

Gases: Air purification, steam filtration, catalyst recovery.

Diffusion: Diffuser screens for gas distribution.

Fluidization: Fluidizing bulk powders in various industrial processes.

Separation: Chromatography frits, centrifuges, nutsche filters.

Other Applications: Breather vents, silencers, filter supports.

| Product name |

Sintered Mesh Filter Disc |

| Type |

Signle layer without edges

Single layer with edged

Multi layer filter disc with edge

Dutch weave filter disc

Spot welded with closed selvaged type

Spot welded without closed selvaged type

Sintered mesh filter disc

Black wire cloth disc

|

| Material |

201 304 304L 316 316L430 etc |

| Weave type |

Plain weave,twilled weave,plain dutch weave,twilled dutch weave,reverse dutch weave |

| Wire diameter |

0.025mm--2.5mm |

| Thickness |

1.0mm---5.0mm |

| Filter rate |

1--200micron |

| Layers |

Single layer or multi layers |

| Shapes |

Rectangle,square,round,oval,circular,cap,waist |

Advantages:

Higher mechanical strength and resistance to deformation.

More consistent and stable pore sizes for reliable filtration.

Improved durability and longer service life.

Easier to clean and reuse.

Can withstand higher pressures and temperatures.

In summary, stainless steel sintered mesh is a high-performance material offering a combination of strength, precision filtration, and durability, making it a preferred choice for demanding filtration and separation applications across diverse industries.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!