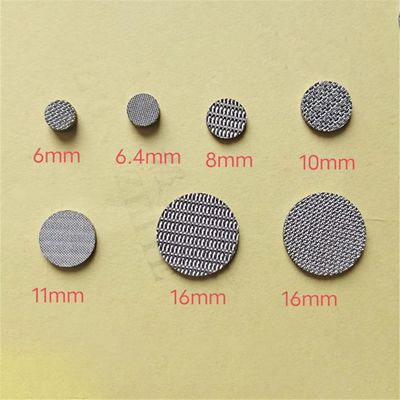

Custom-Cut Precision 0.5-300μm Multi-Layer Sintered Filter Media

Stainless steel sintered mesh is a high-performance filtration material manufactured through advanced layered sintering technology. Composed of multiple layers of precision-woven stainless steel wires, it undergoes high-temperature vacuum sintering to form a rigid porous structure.

This product combines exceptional mechanical strength with uniform filtration precision, making it ideal for demanding industrial applications such as chemical processing, pharmaceuticals, food & beverage, and high-temperature gas filtration.

Available in customizable thicknesses (1-300μm) and sizes, it supports standard specifications (e.g., 100-1500mm length, 25-180mm diameter) or tailored designs.

Ideal for oil & gas, chemical processing, pharmaceuticals, and high-risk industrial applications, it ensures reliable particle retention (1-300μm) while preventing ignition risks in flammable atmospheres. Customizable in diameters (25-1500mm) and thicknesses (1.5-20mm), it supports both gas and liquid media filtration.

Typically made from multiple layers (often 2 to 5) of woven stainless steel wire mesh with varying weave patterns and wire diameters to achieve specific filtration properties.

The sintering process (diffusion bonding) creates a permanent bond at the wire intersections, enhancing the mesh's strength, rigidity, and dimensional stability.

Some designs incorporate a perforated metal layer for added support and robustness. Common stainless steel grades used are 304, 316, and 316L due to their excellent corrosion and temperature resistance.

Applications:

Industrial: Catalyst recovery, hydraulic oil filtration, powder coating systems

Environmental: Wastewater treatment, exhaust gas filtration.

Energy: Fuel filtration, nuclear cooling systems.

Food & Pharma: Sterile air vents, fermentation process control.

Product Features:

Flameproof & Explosion-Resistant Design

Certified for ATEX/IECEx compliance, with a sintered structure that eliminates static sparks and resists combustion in volatile environments.

Multi-Layer Durability

3-5 layers of woven mesh (protection, filtration, support) ensure uniform pore distribution and mechanical strength up to 30MPa

Extreme Environment Adaptability

Resists corrosion from acids, alkalis, and solvents; maintains stability under rapid thermal cycling and high-pressure conditions (≤10MPa)

Customizable Specifications

Tailor wire diameters (0.8-2.0mm), edge sealing (laser-welded/flanged), and shapes (round, square, annular) to fit equipment like reactors or pipelines

Low Maintenance & Reusable

Regenerate via ultrasonic cleaning or reverse flushing without structural degradation, reducing replacement costs

Advantages:

Higher mechanical strength and resistance to deformation.

More consistent and stable pore sizes for reliable filtration.

Improved durability and longer service life.

Easier to clean and reuse.

Can withstand higher pressures and temperatures.

Packaging & Logistics

Anti-corrosion packaging:

wooden case + safety belts + pvc films

paper case + safety belts + pvc films

Global delivery: 7-15 days for samples; 20-30 days for bulk orders.

Why Choose Us?

15+ years of specialized expertise in sintered metal solutions.

Full-spectrum testing: Bubble point, permeability, and tensile strength validation.

24/7 technical support for installation and troubleshooting.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!