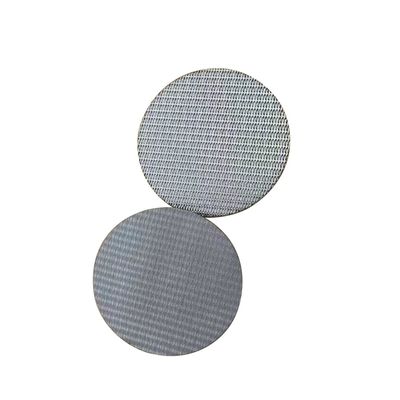

Customization Stainless Steel 304 Sintered Mesh Mesh Filter Disc

The Stainless Steel Sintered Filter Mesh is engineered for critical industrial applications requiring exceptional corrosion resistance and precise filtration. Constructed with multiple layers of high-gradestainless steel through advanced sintering technology, it ensures uniform porosity, high mechanical strength, and long-term durability in harsh environments. Ideal for chemical processing, pharmaceuticals, food and beverage, and wastewater treatment, this filter mesh delivers reliable performance under extreme temperatures (up to 500°C) and aggressive acidic/alkaline conditions.

Product Advantages

Extended Service Life: Resists pitting, cracking, and scaling even in prolonged exposure to acids and chlorides.

High Flow Rate: Optimized porosity minimizes pressure drop, enhancing filtration throughput.

Low Maintenance: Easy to clean via ultrasonic or backflushing methods.

Versatile Applications: Compatible with fuel cells, electrolysis systems, chemical reactors, and more

| Product name |

Sintered Mesh Filter Disc |

| Type |

Signle layer without edges

Single layer with edged

Multi layer filter disc with edge

Dutch weave filter disc

Spot welded with closed selvaged type

Spot welded without closed selvaged type

Sintered mesh filter disc

Black wire cloth disc

|

| Material |

201 304 304L 316 316L430 etc |

| Weave type |

Plain weave,twilled weave,plain dutch weave,twilled dutch weave,reverse dutch weave |

| Wire diameter |

0.025mm--2.5mm |

| Thickness |

1.0mm---5.0mm |

| Filter rate |

1--200micron |

| Layers |

Single layer or multi layers |

| Shapes |

Rectangle,square,round,oval,circular,cap,waist |

Production Process

Material Selection: High-purity stainless steel powder is selected for low carbon content and superior corrosion resistance.

Layer Stacking: Multiple mesh layers are precisely aligned to achieve desired porosity and strength.

Sintering: Processed in a vacuum furnace at 1200–1300°C to fuse particles without melting, ensuring uniform pore distribution

Post-Treatment: Surface polishing and passivation to enhance acid resistance.

Quality Control: Rigorous testing for pore uniformity, pressure resistance, and chemical compatibility.

Why Choose Our Product?

Technical Expertise: Over 10 years of specialization in sintered metal filtration solutions.

Cost-Effective: Reduced downtime and replacement frequency compared to single-layer filters.

24/7 Support: Dedicated engineering team for customization and after-sales service.

Package & delivery

sample

1. stock sample free for customer (more than 50designs in stock )

2. A sample fee will be charged for customized samples, which will be refunded upon the official order

Bulk order

1. by air

2. by sea

3. by express

Support customization

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!